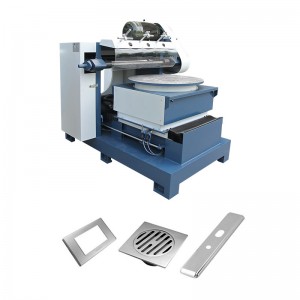

Lock cylinder polishing machine

The lock cylinder polishing machine is specially used to remove sand, polish and polish the customer's copper lock cylinder. The machine adopts multi CNC control system to control the worktable respectively

Move, raise and lower the grinding head, and rotate the workpiece, so as to polish the side of the lock cylinder. While polishing, the workbench can swing back and forth, and the polishing effect is more uniform and detailed. Polishing wheel loss can be automatically compensated.

|

Voltage: |

380v/ 50Hz / Adjustable |

Dimension: |

As actual |

|

Power: |

As actual |

Size of Consumable: |

φ250*50mm / Adjustable |

|

Main Motor: |

3kw / Adjustable |

Consumable Lifting |

100mm / Adjustable |

|

Intermittent: |

5~20s/ Adjustable |

Air Sourcing: |

0.55MPa / Adjustable |

|

Speed of Shaft: |

3000r/min / Adjustable |

Jobs |

4 - 20 jobs / Adjustable |

|

Waxing: |

Automatic |

Consumable swinging |

0~40mm / Adjustable |

A 16-year continuous research and development has cultivated a design team that dares to think and can be implemented. All of them are undergraduate automation majors. The excellent professional skills and the platform we provide make them feel like a duck to water in the industries and fields they are familiar with. , Full of passion and energy, it is the driving force for the sustainable development of our enterprise.

Through the unremitting efforts of the team, it has provided complete solutions for customers in more than 30 countries and regions around the world. In the process of customizing the disc machine, it has kept improving, and has obtained 102 national patents, and has achieved remarkable results. We are still on the road, self-improving, so that our company has always been an innovative leader in the polishing industry.

The application field of this disc polishing machine is very wide, covering tableware, bathroom, lamps, hardware and other special-shaped products, and our equipment can achieve the desired polishing by realizing the rotation of the table and the precise positioning of the polishing wheel. The effect, the polishing time and the number of rotations at the same time can be achieved by adjusting the parameters through the CNC panel, which is very flexible and can meet various requirements.