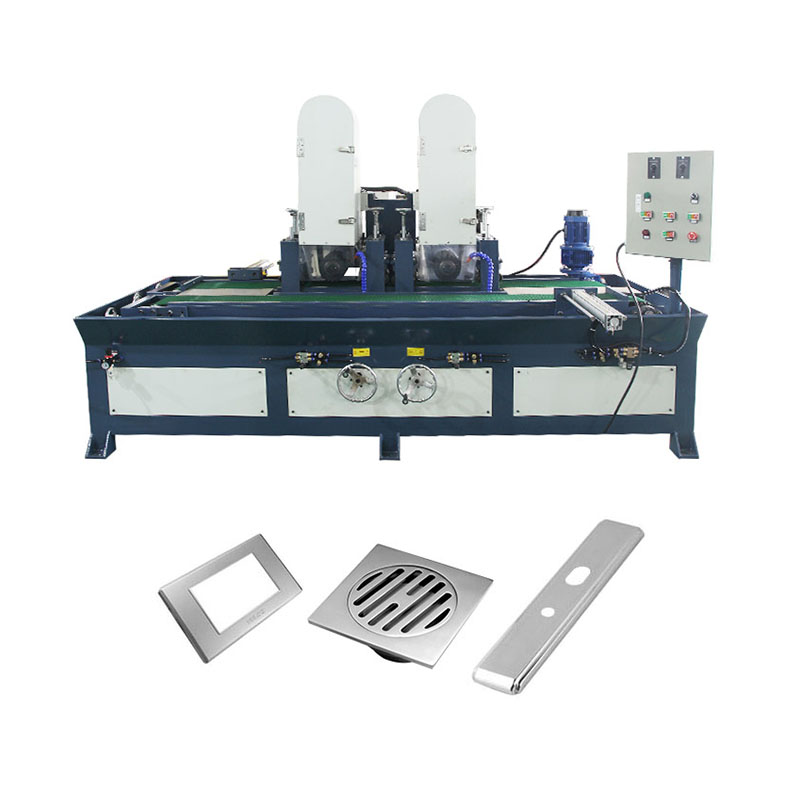

China OEM Stainless Steel Polishing Manufacturers - Abrasive belt water-grinding machine – HaoHan

China OEM Stainless Steel Polishing Manufacturers - Abrasive belt water-grinding machine – HaoHan Detail:

| Model | HH-FL50.01 | HH-FL50.02 | HH-FL50.03 | HH-FL50.04 |

| 2heads-150mm | 2heads-200mm | 4heads-150mm | 6heads-150mm | |

| Option | Economy | Economy | Economy | Economy |

| Voltage | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz |

| Motor | 4kw | 5.5 | 4 | 4 |

| Speed of Shaft | 1800r/min | 1800r/min | 1800r/min | 1800r/min |

| Speed of Feeding | 0~8M/min/Adjustable | 0~8M/min/Adjustable | 0~8M/min/Adjustable | 0~8M/min/Adjustable |

| Warranty | One(1)Year | One(1)Year | One(1)Year | One(1)Year |

| Technical support | video / online | video / online | video / online | video / online |

| Swing range of Belt | 0~40mm | 0~40mm | 0~40mm | |

| Total power | 9.3kw | 12.15kw | 17.7kw | 26.1kw |

| Width of belt | 150mm | 200mm | 150mm | 150mm |

| Heads | 2 | 2 | 4 | 6 |

| Effective width | 10*150mm | 10*200mm | 10*150mm | 10*150mm |

| Effective Thickness | 1~100mm | 1~200mm | 1~150mm | 1~150mm |

| Pump | 0.55Mpa | 0.55Mpa | 0.55Mpa | 0.55Mpa |

| Net weight | 700KGS | 1300KGS | 1900KGS | |

| Dimension(L*W*H) | 2000*1200*1900mm | 2100*1200*1900mm | 3100*1200*1900mm | 4600*1200*1900mm |

| Finishes | hairline/grained | hairline/grained | hairline/grained | hairline/grained |

| Processing | grinding | grinding | grinding | grinding |

| Material workable | All | All | All | All |

| Processing shape | sheet/pipe/panel/… | sheet/pipe/panel/… | sheet/pipe/panel/… | sheet/pipe/panel/… |

| Forth/back/right/left/rotation | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | |

| Outer housing | - | - | - | - |

| Dust Collector / output | - / - | - / - | - / - | - / - |

| Control Pannel / Display | ● / - | ● / - | ● / - | ● / - |

| OEM | acceptable | acceptable | acceptable | acceptable |

| Customization | acceptable | acceptable | acceptable | acceptable |

| MoQ | 10sets | 10sets | 10sets | 10sets |

| Delivery | 30-60days | 30-60days | 30-60days | 30-60days |

| Packing | wooden case | wooden case | wooden case | wooden case |

The main features of its products are stable operation, environmental protection, high safety performance, a wide range of processed products, and high-quality surface treatment.

Sanding, grinding and wire-drawing for panel products. The abrasive belt water-grinding machine is designed with a spray device, which can cool the panel during the grinding processing, and effectively prevent dust pollution, which plays a role in environmental protection.

Finishes achievement:

• Hairline / grained / satin / straight lines / …

In addition,

1. For small products, it can also customize a jig, put the product inside jig and hold it, and then transport it on the conveyor belt for processing.

2. The belt swing function makes the touching between the product and the belt more uniform and achieves a higher-quality finish.

3. The worktable can also adopt a circulating conveying type to process the products back and forth, which is easy to operate, and also effectively improves work efficiency and cost saving.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for China OEM Stainless Steel Polishing Manufacturers - Abrasive belt water-grinding machine – HaoHan , The product will supply to all over the world, such as: Adelaide, Pakistan, Accra, For anyone who is keen on any of our items right after you view our product list, you should definitely feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our merchandise by your self. We're always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!