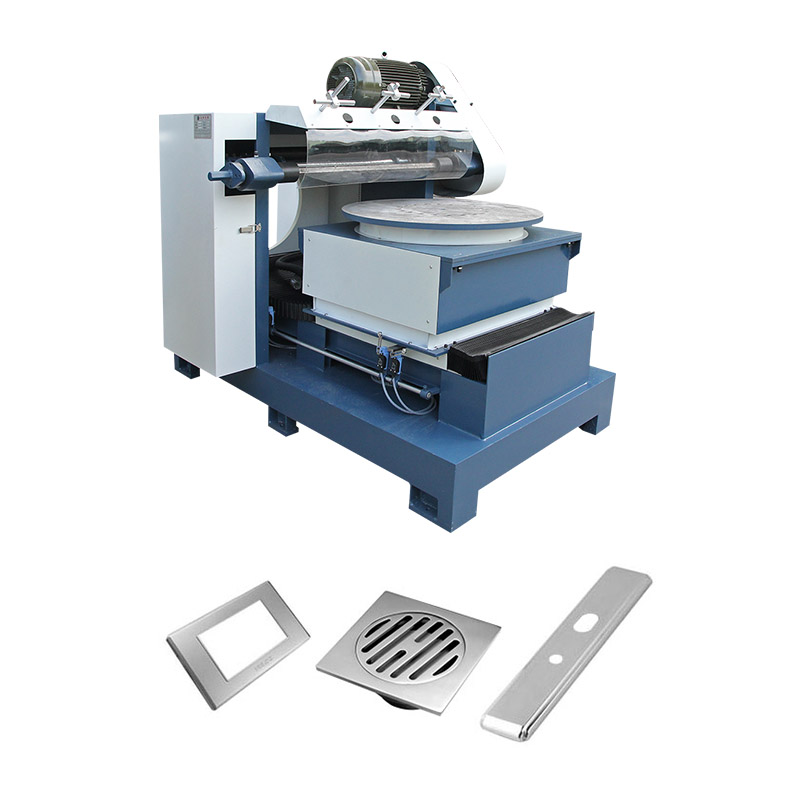

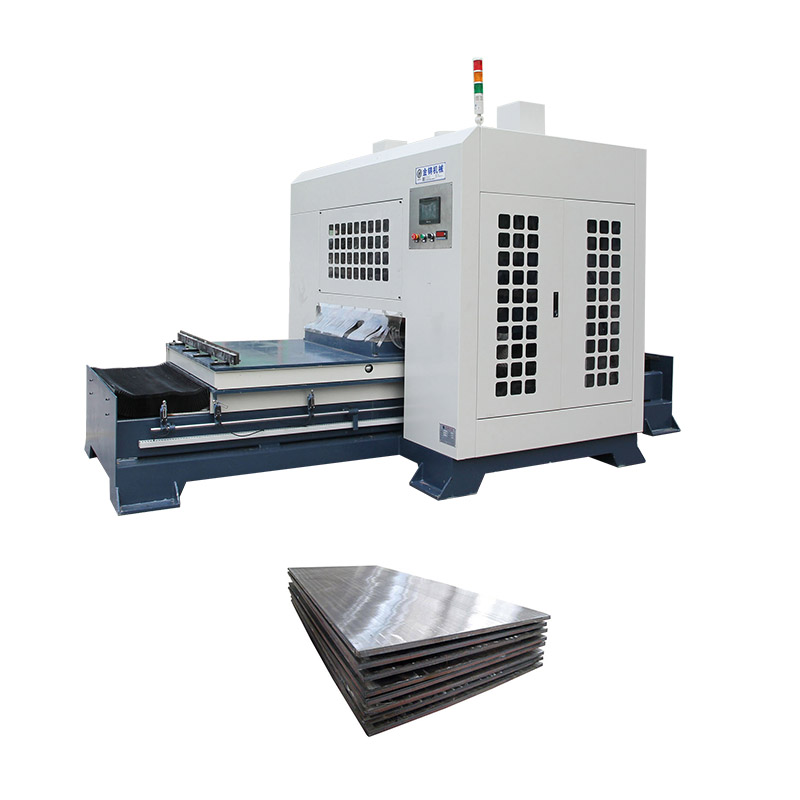

China OEM Rotary Wire Polishing Machine Manufacturers - General flat bar sheet hardware poishing machine on mirror finish – HaoHan

China OEM Rotary Wire Polishing Machine Manufacturers - General flat bar sheet hardware poishing machine on mirror finish – HaoHan Detail:

| Model | HH-FL01.01 | HH-FL01.02 | HH-FL01.03 | HH-FL01.04 | HH-FL01.05 | HH-FL02.01 | HH-FL02.02 |

| Flat 600*600mm | Flat 600*2000mm | Flat 1200*1200mm | Flat 600*600mm | Flat 600*600mm | Flat Dm600mm | Flat Dm850mm | |

| Option | Economy | Economy | Medial | Medial | High | Economy | Economy |

| Voltage | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz |

| Motor | 11kw | 11kw | 15kw | 11kw | 18kw | 12kw | 14kw |

| Speed of Shaft | 1800r/min | 1800r/min | 2800r/min | 1800r/min | 1800r/min | 1800r/min | 1800r/min |

| Consumable/wheel | 600*φ250mm | 600*φ250mm | φ300*1200mm | 600*φ250mm | 600*φ250mm | 600*φ250mm | 600*φ250mm |

| Travel Distance | 80mm | 80mm | 80mm | 80mm | 80mm | 80mm | 80mm |

| Warranty | One(1)Year | One(1)Year | One(1)Year | One(1)Year | One(1)Year | One(1)Year | One(1)Year |

| Technical support | video / online | video / online | video / online | video / online | video / online | video / online | video / online |

| Swing range of worktable | 0~40mm | 0~40mm | 0~40mm | 0~40mm | 0~40mm | 0~40mm | 0~40mm |

| Total power | 11.8kw | 11.8kw | 21.25kw | 11.8kw | 11.8kw | 11.8kw | 11.8kw |

| Dimension of worktable | 600 * 600mm | 600 * 2000mm | 1200 * 1200mm | 600 * 600mm | 600 * 600mm | Dm600mm | Dm850mm |

| Effective max size | 590*590mm | 590*1990mm | 590*1990mm | 590*590mm | 590*590mm | Dm590 | Dm840 |

| Thickness workable | 1~120mm | 1~120mm | 1~120mm | 1~120mm | 1~120mm | 1~120mm | 1~120mm |

| Lifting distance | 200mm | 200mm | 300mm | 200mm | 200mm | 200mm | 200mm |

| Net weight | 700KGS | 1300KGS | 1900KGS | 800KGS | 1100KGS | 800KGS | 1050KGS |

| Dimension | 1500*1500*1700mm | 4600*1500*1700mm | 4000*2400*2200mm | 1500*1500*1700mm | 1500*1500*1700mm | 1500*1500*1700mm | 2100*2100*1700mm |

| Wax | solid / liquid | solid / liquid | solid / liquid | solid / liquid | solid / liquid | solid / liquid | solid / liquid |

| Finishes | mirror / light | mirror / light | mirror / light | mirror / light | mirror / light | mirror / light | mirror / light |

| Processing | polishing / deburring | polishing / deburring | polishing / deburring | polishing / deburring | polishing / deburring | polishing / deburring | polishing / deburring |

| Material workable | All | All | All | All | All | All | All |

| Processing shape | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… |

| Forth/back/right/left/rotation | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / ● | ● /● / ● / ● / ● |

| Outer housing | - | - | ● | ● | ● | - | - |

| Dust Collector / output | - / - | - / - | - / - | - / - | ● /● | - / - | - / - |

| Control Pannel / Display | ● / - | ● / - | ● / - | ● / - | ● /● | ● / - | ● / - |

| Waxing equipment | - | - | ● | ● | ● | - | - |

| Vacuum system/Air pump | - / - | - / - | ● /● | ● /● | ● /● | - / - | - / - |

| OEM | acceptable | acceptable | acceptable | acceptable | acceptable | acceptable | acceptable |

| Customization | acceptable | acceptable | acceptable | acceptable | acceptable | acceptable | acceptable |

| MoQ | 10sets | 10sets | 10sets | 10sets | 10sets | 10sets | 10sets |

| Delivery | 30-60days | 30-60days | 30-60days | 30-60days | 30-60days | 30-60days | 30-60days |

| Packing | wooden case | wooden case | wooden case | wooden case | wooden case | wooden case | wooden case |

The working table of the equipment can be from 600*600~3000mm, which can meet different product specifications, and the fixture can also be customized on this basis. If the product is too small, or use a vacuum suction cup to adsorb the product on the working platform, in this case, it’s more helpful for tight fixing on table during polishing. hence, in order to be having a best approach between wheels and product for high quality achievement. our equipment has added an automatic swing function, so that the polishing wheel can be in uniform contact with the product surface to achieve a higher-precision mirror effect.

In terms of safety, we have a complete circuit design and a good supply chain as a guarantee. ABB, Schneider, and Siemens are all our regular partners.

Finally, if our products can’t meet your requirement, please contact us, as we are specialized in ingenuity. We tailor a complete solution as per your actual requirement. We have a strong R&D and designing team, professional and feasible plan is our basis for delivery of the turnkey project.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients' gratification for China OEM Rotary Wire Polishing Machine Manufacturers - General flat bar sheet hardware poishing machine on mirror finish – HaoHan , The product will supply to all over the world, such as: Bandung, Rotterdam, Moldova, Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So you should feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we are going to surely present you with the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we'll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we're here to welcome your inquiries for any of our merchandise and service.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.