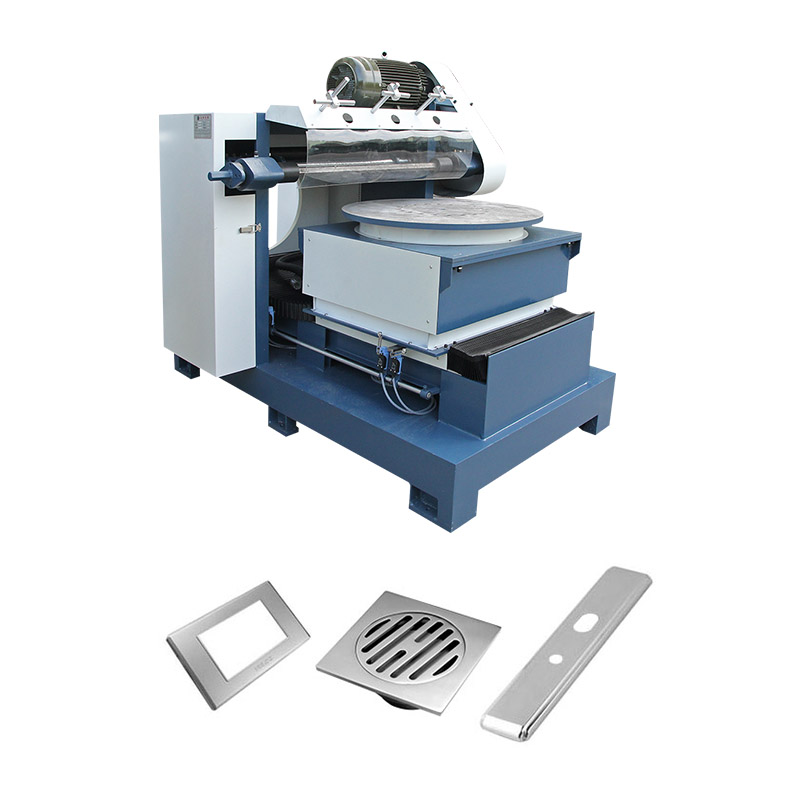

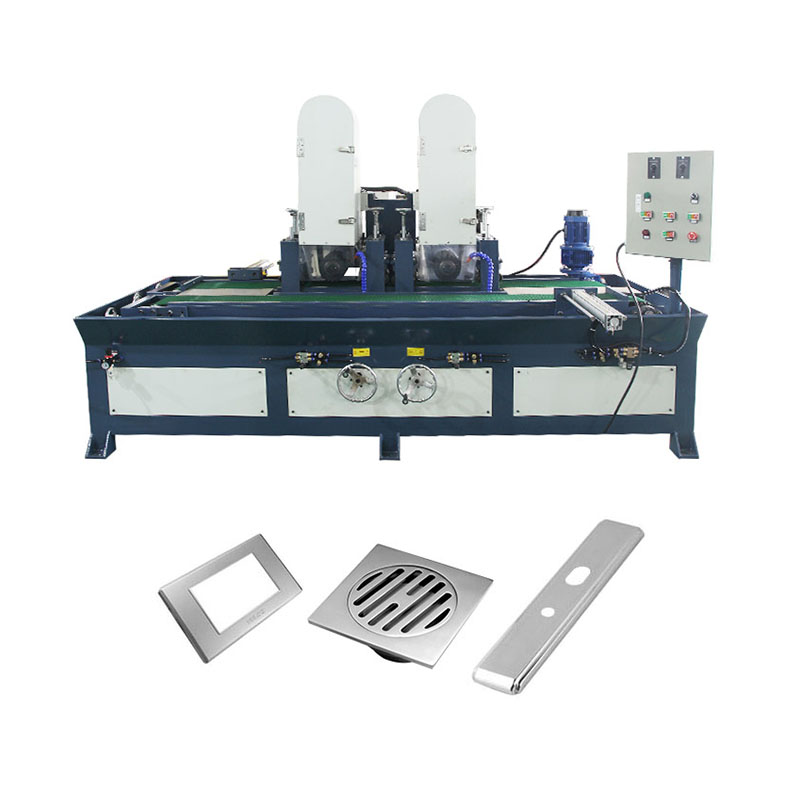

China OEM Mirror Finish Polish Manufacturers - Abrasive belt water-grinding machine – HaoHan

China OEM Mirror Finish Polish Manufacturers - Abrasive belt water-grinding machine – HaoHan Detail:

| Model | HH-FL50.01 | HH-FL50.02 | HH-FL50.03 | HH-FL50.04 |

| 2heads-150mm | 2heads-200mm | 4heads-150mm | 6heads-150mm | |

| Option | Economy | Economy | Economy | Economy |

| Voltage | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz |

| Motor | 4kw | 5.5 | 4 | 4 |

| Speed of Shaft | 1800r/min | 1800r/min | 1800r/min | 1800r/min |

| Speed of Feeding | 0~8M/min/Adjustable | 0~8M/min/Adjustable | 0~8M/min/Adjustable | 0~8M/min/Adjustable |

| Warranty | One(1)Year | One(1)Year | One(1)Year | One(1)Year |

| Technical support | video / online | video / online | video / online | video / online |

| Swing range of Belt | 0~40mm | 0~40mm | 0~40mm | |

| Total power | 9.3kw | 12.15kw | 17.7kw | 26.1kw |

| Width of belt | 150mm | 200mm | 150mm | 150mm |

| Heads | 2 | 2 | 4 | 6 |

| Effective width | 10*150mm | 10*200mm | 10*150mm | 10*150mm |

| Effective Thickness | 1~100mm | 1~200mm | 1~150mm | 1~150mm |

| Pump | 0.55Mpa | 0.55Mpa | 0.55Mpa | 0.55Mpa |

| Net weight | 700KGS | 1300KGS | 1900KGS | |

| Dimension(L*W*H) | 2000*1200*1900mm | 2100*1200*1900mm | 3100*1200*1900mm | 4600*1200*1900mm |

| Finishes | hairline/grained | hairline/grained | hairline/grained | hairline/grained |

| Processing | grinding | grinding | grinding | grinding |

| Material workable | All | All | All | All |

| Processing shape | sheet/pipe/panel/… | sheet/pipe/panel/… | sheet/pipe/panel/… | sheet/pipe/panel/… |

| Forth/back/right/left/rotation | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | |

| Outer housing | - | - | - | - |

| Dust Collector / output | - / - | - / - | - / - | - / - |

| Control Pannel / Display | ● / - | ● / - | ● / - | ● / - |

| OEM | acceptable | acceptable | acceptable | acceptable |

| Customization | acceptable | acceptable | acceptable | acceptable |

| MoQ | 10sets | 10sets | 10sets | 10sets |

| Delivery | 30-60days | 30-60days | 30-60days | 30-60days |

| Packing | wooden case | wooden case | wooden case | wooden case |

The main features of its products are stable operation, environmental protection, high safety performance, a wide range of processed products, and high-quality surface treatment.

Sanding, grinding and wire-drawing for panel products. The abrasive belt water-grinding machine is designed with a spray device, which can cool the panel during the grinding processing, and effectively prevent dust pollution, which plays a role in environmental protection.

Finishes achievement:

• Hairline / grained / satin / straight lines / …

In addition,

1. For small products, it can also customize a jig, put the product inside jig and hold it, and then transport it on the conveyor belt for processing.

2. The belt swing function makes the touching between the product and the belt more uniform and achieves a higher-quality finish.

3. The worktable can also adopt a circulating conveying type to process the products back and forth, which is easy to operate, and also effectively improves work efficiency and cost saving.

Product detail pictures:

Related Product Guide:

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for China OEM Mirror Finish Polish Manufacturers - Abrasive belt water-grinding machine – HaoHan , The product will supply to all over the world, such as: Iraq, Belize, Los Angeles, With the first-class products, excellent service, fast delivery and the best price, we have won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!