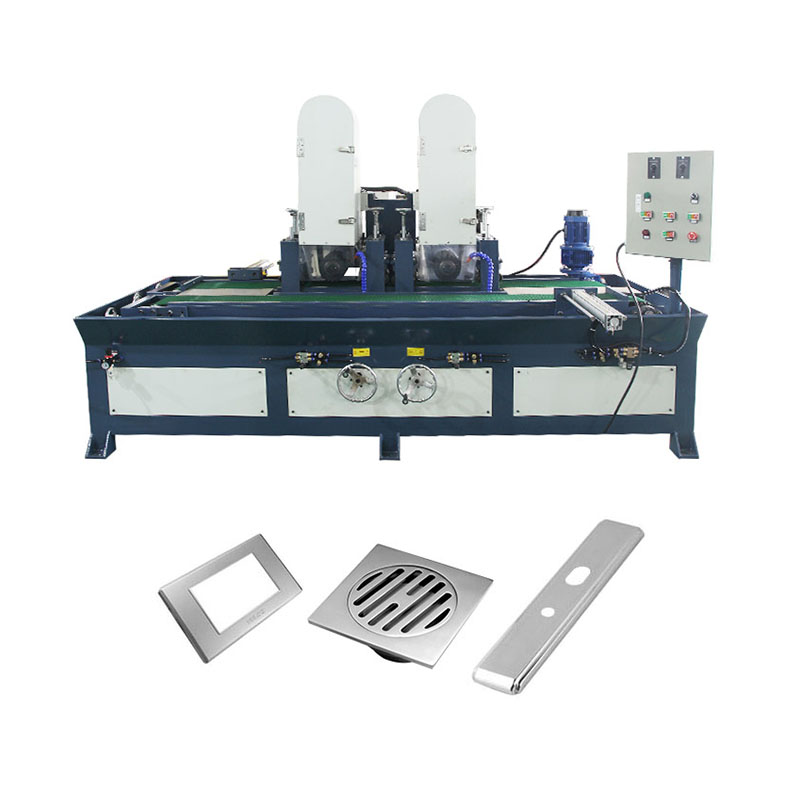

China OEM Legacy Metal Polish Suppliers - Abrasive belt water-grinding machine – HaoHan

China OEM Legacy Metal Polish Suppliers - Abrasive belt water-grinding machine – HaoHan Detail:

| Model | HH-FL50.01 | HH-FL50.02 | HH-FL50.03 | HH-FL50.04 |

| 2heads-150mm | 2heads-200mm | 4heads-150mm | 6heads-150mm | |

| Option | Economy | Economy | Economy | Economy |

| Voltage | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz |

| Motor | 4kw | 5.5 | 4 | 4 |

| Speed of Shaft | 1800r/min | 1800r/min | 1800r/min | 1800r/min |

| Speed of Feeding | 0~8M/min/Adjustable | 0~8M/min/Adjustable | 0~8M/min/Adjustable | 0~8M/min/Adjustable |

| Warranty | One(1)Year | One(1)Year | One(1)Year | One(1)Year |

| Technical support | video / online | video / online | video / online | video / online |

| Swing range of Belt | 0~40mm | 0~40mm | 0~40mm | |

| Total power | 9.3kw | 12.15kw | 17.7kw | 26.1kw |

| Width of belt | 150mm | 200mm | 150mm | 150mm |

| Heads | 2 | 2 | 4 | 6 |

| Effective width | 10*150mm | 10*200mm | 10*150mm | 10*150mm |

| Effective Thickness | 1~100mm | 1~200mm | 1~150mm | 1~150mm |

| Pump | 0.55Mpa | 0.55Mpa | 0.55Mpa | 0.55Mpa |

| Net weight | 700KGS | 1300KGS | 1900KGS | |

| Dimension(L*W*H) | 2000*1200*1900mm | 2100*1200*1900mm | 3100*1200*1900mm | 4600*1200*1900mm |

| Finishes | hairline/grained | hairline/grained | hairline/grained | hairline/grained |

| Processing | grinding | grinding | grinding | grinding |

| Material workable | All | All | All | All |

| Processing shape | sheet/pipe/panel/… | sheet/pipe/panel/… | sheet/pipe/panel/… | sheet/pipe/panel/… |

| Forth/back/right/left/rotation | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | |

| Outer housing | - | - | - | - |

| Dust Collector / output | - / - | - / - | - / - | - / - |

| Control Pannel / Display | ● / - | ● / - | ● / - | ● / - |

| OEM | acceptable | acceptable | acceptable | acceptable |

| Customization | acceptable | acceptable | acceptable | acceptable |

| MoQ | 10sets | 10sets | 10sets | 10sets |

| Delivery | 30-60days | 30-60days | 30-60days | 30-60days |

| Packing | wooden case | wooden case | wooden case | wooden case |

The main features of its products are stable operation, environmental protection, high safety performance, a wide range of processed products, and high-quality surface treatment.

Sanding, grinding and wire-drawing for panel products. The abrasive belt water-grinding machine is designed with a spray device, which can cool the panel during the grinding processing, and effectively prevent dust pollution, which plays a role in environmental protection.

Finishes achievement:

• Hairline / grained / satin / straight lines / …

In addition,

1. For small products, it can also customize a jig, put the product inside jig and hold it, and then transport it on the conveyor belt for processing.

2. The belt swing function makes the touching between the product and the belt more uniform and achieves a higher-quality finish.

3. The worktable can also adopt a circulating conveying type to process the products back and forth, which is easy to operate, and also effectively improves work efficiency and cost saving.

Product detail pictures:

Related Product Guide:

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for China OEM Legacy Metal Polish Suppliers - Abrasive belt water-grinding machine – HaoHan , The product will supply to all over the world, such as: Bandung, Uzbekistan, Netherlands, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.