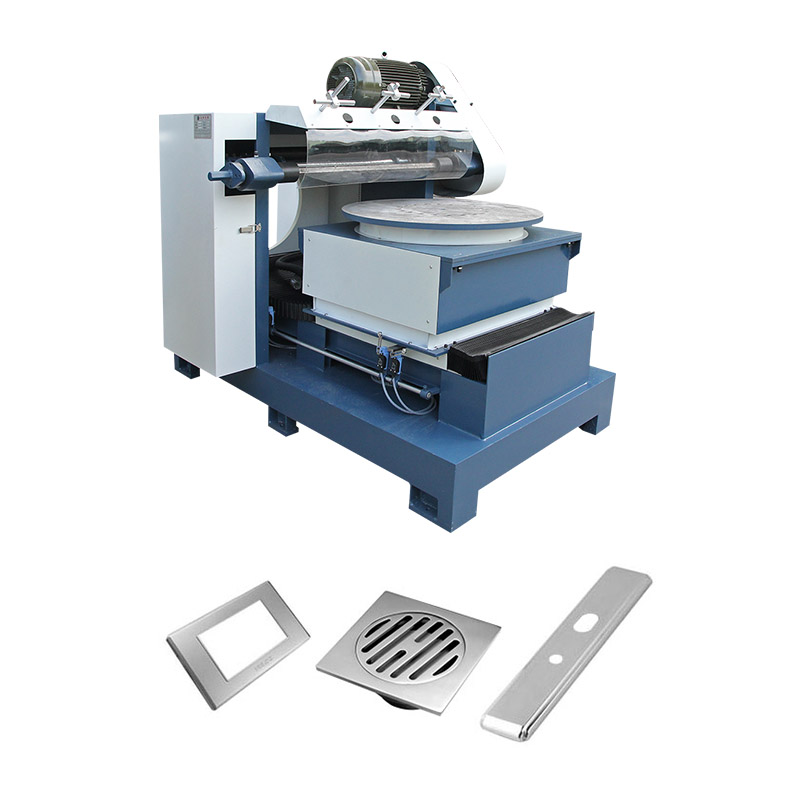

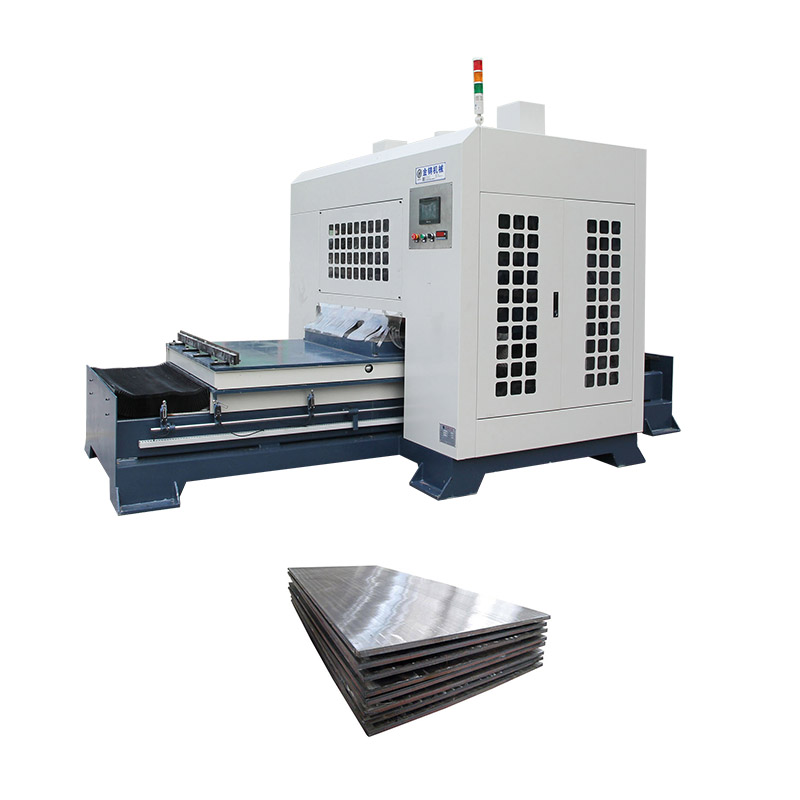

China OEM Grinding Wheels Manufacturers - General flat bar sheet hardware poishing machine on mirror finish – HaoHan

China OEM Grinding Wheels Manufacturers - General flat bar sheet hardware poishing machine on mirror finish – HaoHan Detail:

| Model | HH-FL01.01 | HH-FL01.02 | HH-FL01.03 | HH-FL01.04 | HH-FL01.05 | HH-FL02.01 | HH-FL02.02 |

| Flat 600*600mm | Flat 600*2000mm | Flat 1200*1200mm | Flat 600*600mm | Flat 600*600mm | Flat Dm600mm | Flat Dm850mm | |

| Option | Economy | Economy | Medial | Medial | High | Economy | Economy |

| Voltage | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz | 380v/50Hz |

| Motor | 11kw | 11kw | 15kw | 11kw | 18kw | 12kw | 14kw |

| Speed of Shaft | 1800r/min | 1800r/min | 2800r/min | 1800r/min | 1800r/min | 1800r/min | 1800r/min |

| Consumable/wheel | 600*φ250mm | 600*φ250mm | φ300*1200mm | 600*φ250mm | 600*φ250mm | 600*φ250mm | 600*φ250mm |

| Travel Distance | 80mm | 80mm | 80mm | 80mm | 80mm | 80mm | 80mm |

| Warranty | One(1)Year | One(1)Year | One(1)Year | One(1)Year | One(1)Year | One(1)Year | One(1)Year |

| Technical support | video / online | video / online | video / online | video / online | video / online | video / online | video / online |

| Swing range of worktable | 0~40mm | 0~40mm | 0~40mm | 0~40mm | 0~40mm | 0~40mm | 0~40mm |

| Total power | 11.8kw | 11.8kw | 21.25kw | 11.8kw | 11.8kw | 11.8kw | 11.8kw |

| Dimension of worktable | 600 * 600mm | 600 * 2000mm | 1200 * 1200mm | 600 * 600mm | 600 * 600mm | Dm600mm | Dm850mm |

| Effective max size | 590*590mm | 590*1990mm | 590*1990mm | 590*590mm | 590*590mm | Dm590 | Dm840 |

| Thickness workable | 1~120mm | 1~120mm | 1~120mm | 1~120mm | 1~120mm | 1~120mm | 1~120mm |

| Lifting distance | 200mm | 200mm | 300mm | 200mm | 200mm | 200mm | 200mm |

| Net weight | 700KGS | 1300KGS | 1900KGS | 800KGS | 1100KGS | 800KGS | 1050KGS |

| Dimension | 1500*1500*1700mm | 4600*1500*1700mm | 4000*2400*2200mm | 1500*1500*1700mm | 1500*1500*1700mm | 1500*1500*1700mm | 2100*2100*1700mm |

| Wax | solid / liquid | solid / liquid | solid / liquid | solid / liquid | solid / liquid | solid / liquid | solid / liquid |

| Finishes | mirror / light | mirror / light | mirror / light | mirror / light | mirror / light | mirror / light | mirror / light |

| Processing | polishing / deburring | polishing / deburring | polishing / deburring | polishing / deburring | polishing / deburring | polishing / deburring | polishing / deburring |

| Material workable | All | All | All | All | All | All | All |

| Processing shape | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… | sheet/pipe/tube/… |

| Forth/back/right/left/rotation | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / - | ● /● / ● / ● / ● | ● /● / ● / ● / ● |

| Outer housing | - | - | ● | ● | ● | - | - |

| Dust Collector / output | - / - | - / - | - / - | - / - | ● /● | - / - | - / - |

| Control Pannel / Display | ● / - | ● / - | ● / - | ● / - | ● /● | ● / - | ● / - |

| Waxing equipment | - | - | ● | ● | ● | - | - |

| Vacuum system/Air pump | - / - | - / - | ● /● | ● /● | ● /● | - / - | - / - |

| OEM | acceptable | acceptable | acceptable | acceptable | acceptable | acceptable | acceptable |

| Customization | acceptable | acceptable | acceptable | acceptable | acceptable | acceptable | acceptable |

| MoQ | 10sets | 10sets | 10sets | 10sets | 10sets | 10sets | 10sets |

| Delivery | 30-60days | 30-60days | 30-60days | 30-60days | 30-60days | 30-60days | 30-60days |

| Packing | wooden case | wooden case | wooden case | wooden case | wooden case | wooden case | wooden case |

The working table of the equipment can be from 600*600~3000mm, which can meet different product specifications, and the fixture can also be customized on this basis. If the product is too small, or use a vacuum suction cup to adsorb the product on the working platform, in this case, it’s more helpful for tight fixing on table during polishing. hence, in order to be having a best approach between wheels and product for high quality achievement. our equipment has added an automatic swing function, so that the polishing wheel can be in uniform contact with the product surface to achieve a higher-precision mirror effect.

In terms of safety, we have a complete circuit design and a good supply chain as a guarantee. ABB, Schneider, and Siemens are all our regular partners.

Finally, if our products can’t meet your requirement, please contact us, as we are specialized in ingenuity. We tailor a complete solution as per your actual requirement. We have a strong R&D and designing team, professional and feasible plan is our basis for delivery of the turnkey project.

Product detail pictures:

Related Product Guide:

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for China OEM Grinding Wheels Manufacturers - General flat bar sheet hardware poishing machine on mirror finish – HaoHan , The product will supply to all over the world, such as: Lesotho, Danish, Cancun, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!